One I production update May

Share

Hi everyone,

how's your spring? It's been unusually rainy here in Tuebingen which makes the weather cooler, but the bees, wasps and other forms of young organic life are starting to find their way into werk.technica HQ, making writing this update real fun.

Well. There's going to be a lot of technical information in this update so let's get to it! Should you be bored by all the technical detail, there is a tl;dr somewhere at the bottom of this wall of text.

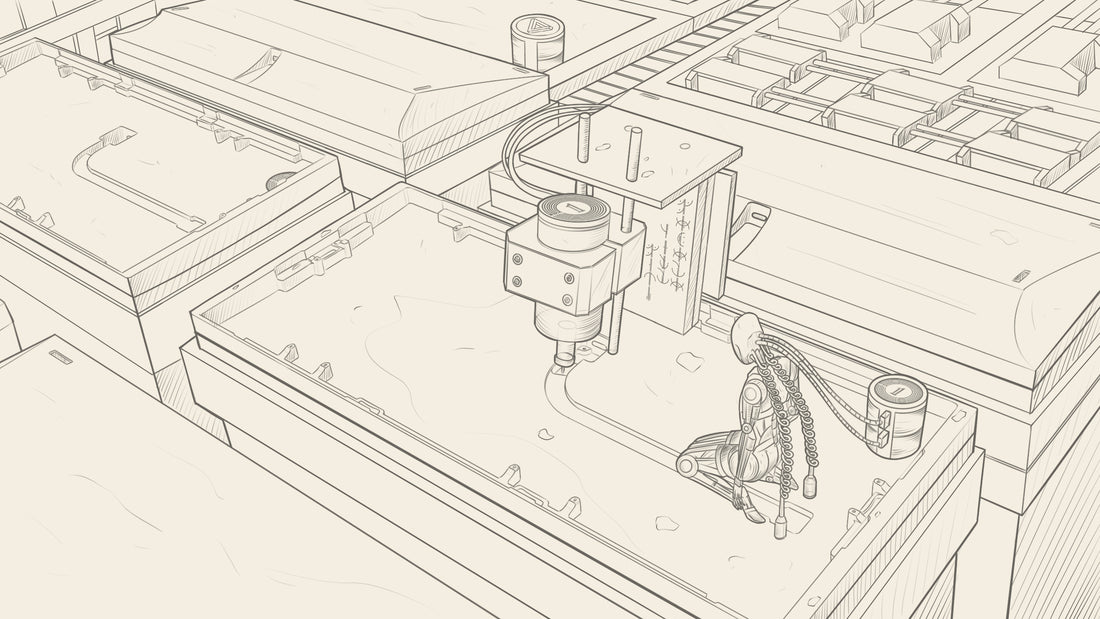

Back in winter 2022/23 we decided to begin the production with the most complicated part of Werk One, the monolithic curved bottom body. Most of the boards that people pre-ordered are copper and brass variants of the One. Ordering such high amounts of brass and copper was new for us, new for our factory, and new for the suppliers as well. Due to the monolithic design of Werk One, the metal had to be cut into a much larger chunk than what the suppliers are usually used to.

Another thing was that handling such a giant piece of expensive material like this was very risky for our factory employees. One misstep was enough for such a large piece to be wasted.

And finally, we had to be careful about the quality of the material we got from our suppliers. We had to order smaller chunks of copper and brass from our suppliers, produce a sample and decide if the quality of the metal was up to our standard.

All of those steps have been time-consuming, but when the large-scale production began everything fit in its place. The CNC production step of Werk One bottom parts is finished. This goes for aluminum, brass and copper pieces. Currently we are laser engraving them, which is a rather straightforward process.

Here some impressions from CNC milling process:

Werk One top parts are currently in CNC and should be finished too sometime this month.

Currently we are preparing for surface treatment which is tricky again because of how big and complex the bottom piece of Werk One design is.

Usually, the piece that goes into anodization / e-coat bath is secured by a rack. Such a rack holds 6-10 units usually, but because of the sheer size and weight of the One bottom part, we had to produce custom racks. Even our custom produced rack will fit only 6 pieces, which considerably increases the surface treatment time. Additionally, we have to be very careful with the oxidation of copper pieces since they start to oxidize right after the bead blasting process while they are on their way into the coating bath. All those steps needed a very careful planning on our end. At this point, we believe to be very much on track to deliver a product that lives up to our high quality standard.

We will cover more technical aspects of the surface treatment as well as the prototyping of Werk Instrument and the M-01 OLED module in the next update.

Apart of the main Werk One production, we are preparing the packaging. We heard you and are aware that most of you would prefer a nice case, so we are prototyping cases along side with regular packaging right now and will decide which we will go with after we receive the final round of samples of both.

Finally, we have to address the situation with mykeyboard.eu since many of you decided to purchase Werk One from them. Apart from the technical hook ups we expected, there was a production delay caused by the very slow payment to our production partner by mkeu. Their main production payment was finally placed and their part of production is on track. While legally people who purchased from mkeu are mkeu and not our customers, its important to us that this part of the run goes as smoothly as the rest. We are doing our best to keep it that way and adjust the project payment schedule with possible delays by MKEU back in mind. Still, it was our choice of distribution partner and we sincerely apologize for the delay caused and promise to be more careful with distribution partners in the future.

WHERE DOES ALL OF THAT PUT THE RELEASE DATE? We'll probably be able to start shipping sometime end of this summer / fall, depending on how fast the shipping and customs processes will be. We are expecting a limited number of extras to be available and ready to ship by that time too.

tl;dr

You’ve probably jumped here. Good on you.

- Werk One bottom pieces CNC production is finished

- Werk One top pieces CNC production is almost finished, with target being this month

- Surface treatment is prepared with custom racks produced for Werk One only

- Depending on the quality of packaging samples which we will receive soon, we will decide on the big box / case question

- Mkeu buyers, the payment was placed, we have your back

- Fulfillment target is end of this summer / fall

- Yes, there will be a limited number of extras

Here some insights from our factory workshop, before the boards head to surface treatment.

Apart from Werk One production we are working on finalizing Werk Instrument and you can expect the reveal of Werk Triad we been working on past 2 years this summer.

Thanks for all your patience! ❤

Zaum out